Sector

You are here:

- Home

- Sector

Sector

You are here:

- Home

- Sector

Nothing found

Test Laboratories

Semiconductor Manufacturing

Process Control

Infrastructure Testing and Monitoring

Acoustic Testing

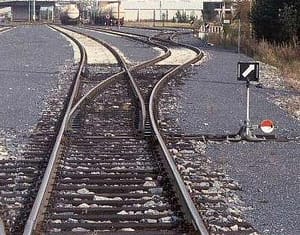

Rail & Road

Wheel Profile

Overview

Wheel profile refers to the specific shape and contour of wheels used in rail and road vehicles, ensuring optimal contact with tracks or surfaces for efficient performance.Key Components

- Tread: The outer surface that contacts the rail or road.

- Flange: Raised edge on rail wheels to prevent derailment.

- Diameter: Varies depending on the vehicle type and purpose.

- Profile Shape: Designed to balance wear, stability, and traction.

Importance

- Safety: Ensures stability and prevents derailment or skidding.

- Efficiency: Reduces rolling resistance for smoother motion.

- Wear Management: Minimizes wheel and track wear.

Applications

- Rail transport systems

- Heavy vehicles

- High-speed trains

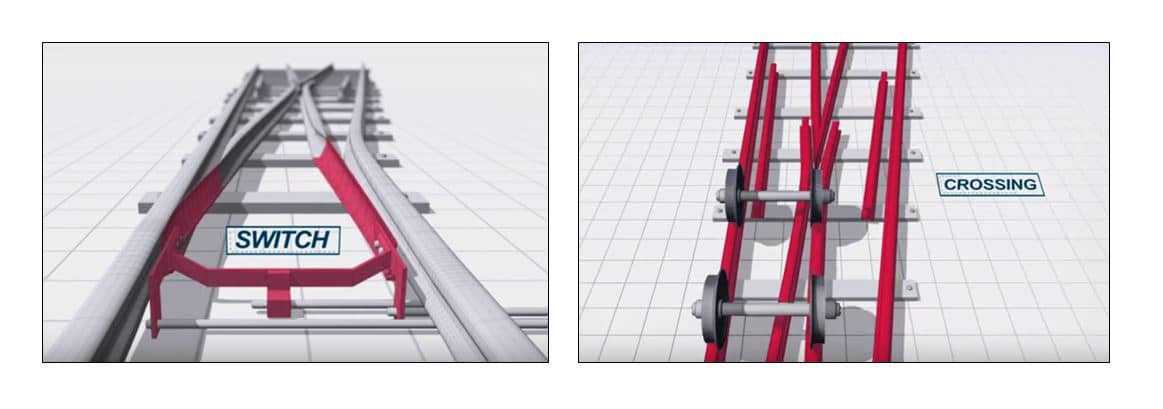

Switch & Crossing

Overview

Switches and crossings (S&C) are critical components of railway infrastructure, enabling trains to move from one track to another and safely navigate track intersections.Key Components

- Switch: Mechanism that guides trains from one track to another.

- Crossing: Allows wheels to pass over intersecting rails.

- Frog: Intersection point where tracks cross.

- Point Blades: Movable rails that direct train wheels onto different tracks.

Functions

- Track Diversion: Enables trains to switch tracks smoothly.

- Safe Navigation: Ensures trains pass intersections without derailment.

- Operational Flexibility: Allows complex rail network management.

Applications

- Railway junctions

- High-speed train networks

- Urban transit systems

Sleeper Testing

Overview

Sleeper testing involves evaluating railway sleepers (also known as ties) to ensure their structural integrity and performance under operational loads.Key Components

- Sleeper Material: Typically concrete, wood, or composite materials.

- Load Testing: Applying weight to assess load-bearing capacity.

- Inspection: Checking for defects, cracks, or deterioration.

- Instrumentation: Using sensors to measure stress and deformation.

Importance

- Safety: Ensures sleepers can support track loads safely.

- Durability: Assesses the lifespan and resistance to wear.

- Maintenance: Identifies sleepers in need of repair or replacement.

Applications

- Railway track maintenance

- Infrastructure assessment

- Quality control in sleeper manufacturing

Rail Testing

Overview

Rail testing involves evaluating the quality and safety of railway tracks to ensure their performance and longevity under operational conditions.Key Components

- Track Inspection: Visual and technical checks for defects or wear.

- Ultrasonic Testing: Detects internal flaws using sound waves.

- Dynamic Testing: Assesses track performance under simulated train loads.

- Measurement Systems: Instruments for assessing rail alignment and gauge.

Importance

- Safety: Prevents accidents due to rail defects.

- Performance: Ensures smooth and efficient train operations.

- Maintenance: Identifies areas needing repair or replacement.

Applications

- Routine track maintenance

- Pre-service rail evaluations

- Infrastructure safety audits

Break Testing

Overview

Brake testing evaluates the performance and safety of braking systems in rail and road vehicles to ensure effective stopping power and reliability.Key Components

- Brake Testers: Devices used to measure braking force and performance.

- Load Cells: Sensors that record braking force applied.

- Simulation Equipment: Assesses brake response under various conditions.

- Data Analysis: Software to analyze braking performance and safety metrics.

Importance

- Safety: Ensures brakes perform reliably under operational conditions.

- Regulatory Compliance: Meets safety standards and regulations.

- Maintenance: Identifies issues requiring repair or adjustment.

Applications

- Vehicle safety inspections

- Pre-service and post-service brake checks

- Fleet maintenance programs

Power Plants

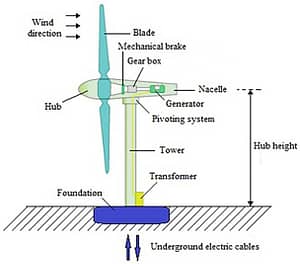

Wind Energy

Overview

Wind energy is a renewable energy source generated by converting the kinetic energy of wind into electricity through wind turbines.

Key Components

- Wind Turbines: Convert wind energy into mechanical power.

- Generator: Transforms mechanical power into electricity.

- Control Systems: Regulate turbine operation based on wind speed.

- Power Grid Integration: Connects generated electricity to the grid.

- Sustainable: Wind energy is a clean, renewable resource.

- Cost-Effective: Reduces dependency on fossil fuels.

- Scalable: Can be deployed in various capacities, from small-scale to large wind farms.

- Offshore wind farms

- Onshore wind power plants

- Hybrid energy systems

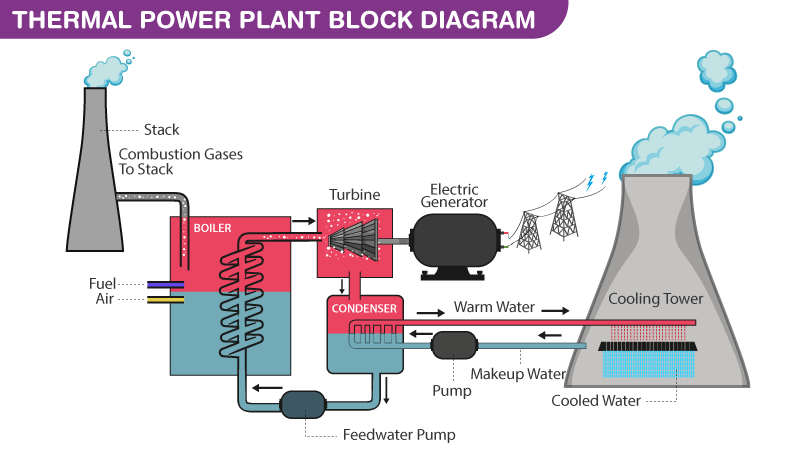

Thermal Power Plant

Overview

Thermal power plants generate electricity by converting heat energy, typically from the combustion of fossil fuels, into electrical power.Key Components

- Boiler: Heats water to produce steam.

- Turbine: Converts steam energy into mechanical power.

- Generator: Converts mechanical power into electricity.

- Condenser: Cools steam back into water for reuse.

Processes

- Combustion: Fuels like coal, oil, or gas are burned to generate heat.

- Steam Cycle: Steam drives turbines to generate electricity.

- Cooling: Steam is condensed for reuse.

Applications

- Base-load electricity generation

- Industrial energy supply

- Grid stability support

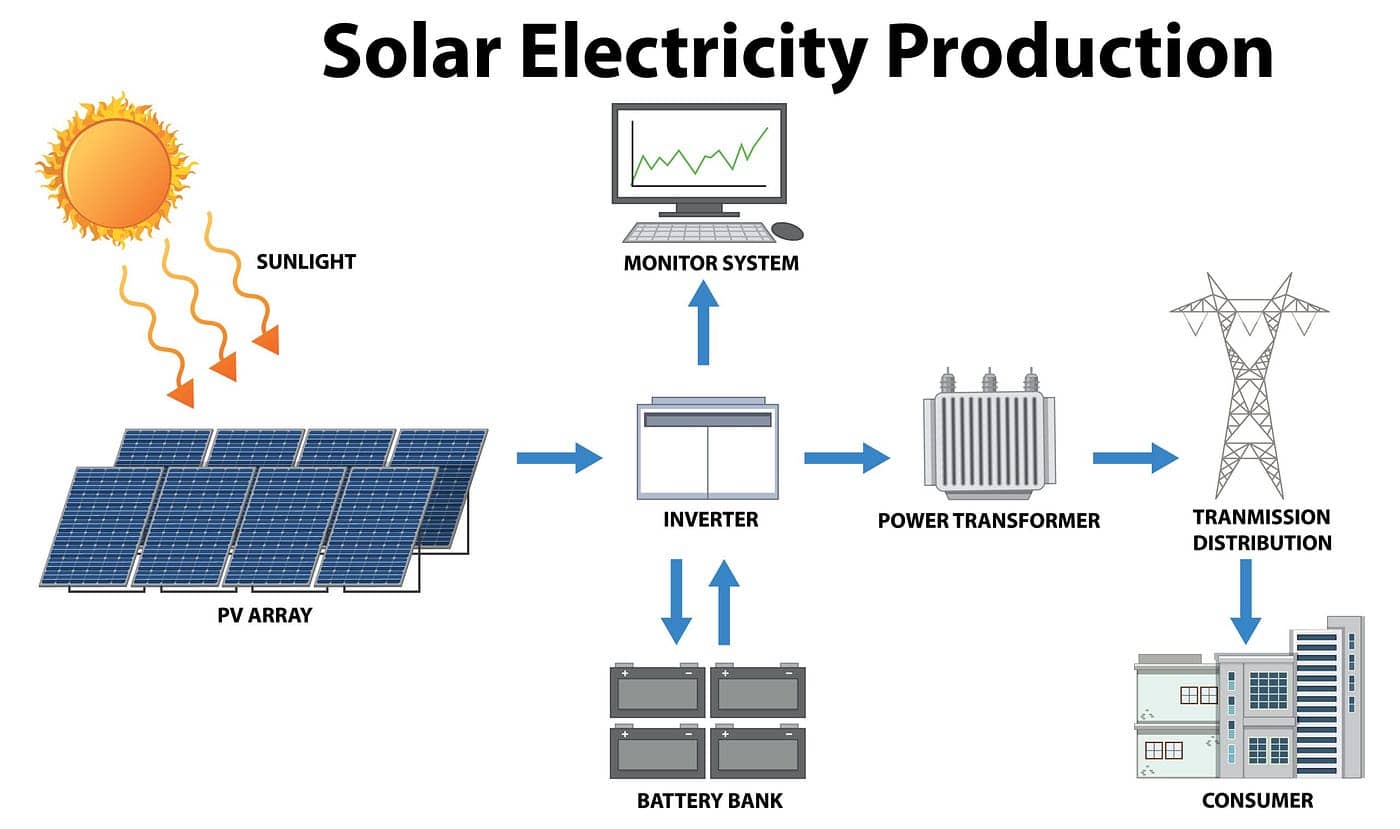

Solar Industry

Overview

The solar industry harnesses energy from the sun to generate electricity using photovoltaic (PV) panels or solar thermal systems, providing a clean and renewable energy source.Key Components

- Solar Panels: Convert sunlight into electricity.

- Inverters: Convert direct current (DC) from panels to alternating current (AC).

- Batteries: Store excess energy for later use.

- Mounting Systems: Hold solar panels in place for optimal sun exposure.

Benefits

- Renewable: Solar energy is abundant and eco-friendly.

- Low Operating Costs: Minimal maintenance after installation.

- Scalable: Suitable for residential, commercial, and utility-scale projects.

Applications

- Residential solar power systems

- Solar farms

- Hybrid energy solutions

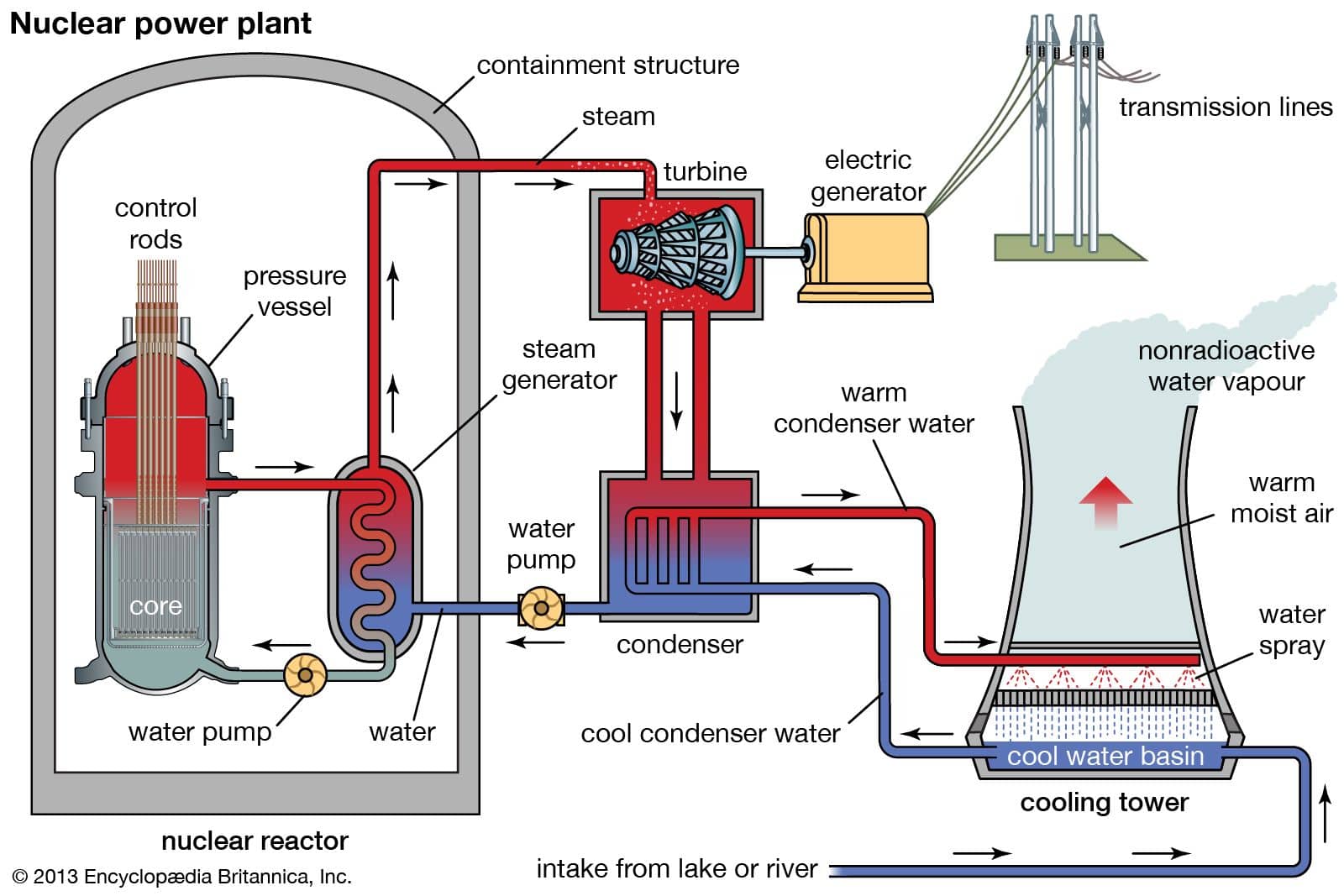

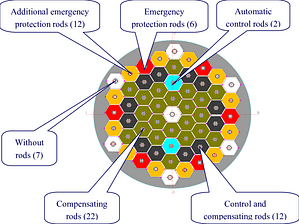

Nuclear Power Plant

Overview

Nuclear power plants generate electricity by harnessing energy from nuclear fission reactions, providing a reliable and large-scale energy source.Key Components

- Reactor: Contains nuclear fuel and initiates fission reactions.

- Steam Generator: Transfers heat from the reactor to produce steam.

- Turbine: Converts steam energy into mechanical power.

- Cooling System: Cools down the reactor and steam after energy generation.

Processes

- Nuclear Fission: Splitting of uranium or plutonium atoms releases energy.

- Steam Cycle: Generated steam drives turbines to produce electricity.

- Cooling: Used to maintain safe reactor temperatures.

Applications

- Base-load electricity generation

- Grid stabilization

- Industrial energy supply

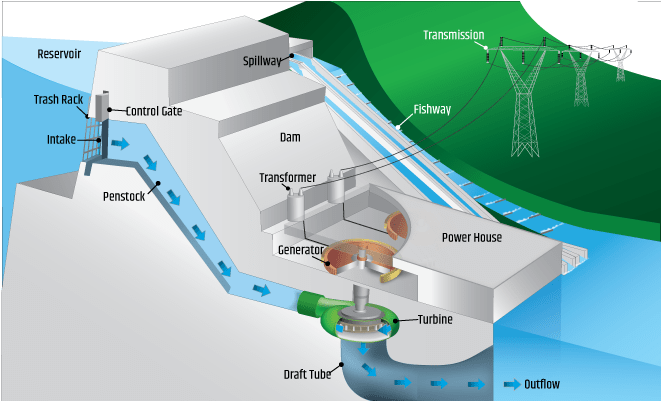

Hydraulic Dams

Overview

Hydraulic dams generate electricity through hydropower by utilizing the energy of flowing or falling water to drive turbines, offering a renewable energy source.

Key Components

- Dam Structure: Stores water and controls its flow.

- Reservoir: Collects and stores water.

- Turbines: Convert the kinetic energy of water into mechanical power.

- Generator: Converts mechanical power into electricity.

Processes

- Water Flow: Controlled release of water drives turbines.

- Energy Conversion: Water’s kinetic energy is converted into electricity.

- Power Distribution: Electricity is transmitted to the grid.

Applications

- Large-scale electricity production

- Irrigation and flood control

- Water resource management

Oil & Gas

Vibration Sensors Calibrators

Overview

Calibration of vibration sensors ensures accurate and reliable data in oil and gas operations, crucial for equipment monitoring and safety.

Importance

Proper calibration prevents machinery failure, reduces downtime, and ensures compliance with industry standards.Calibration Process

- Pre-Calibration Inspection: Assess sensor condition.

- Reference Standards: Use traceable standards for comparison.

- Calibration Methods: Perform calibration under controlled conditions.

- Data Analysis: Validate sensor accuracy.

Frequency of Calibration

Regular intervals based on operational demands and manufacturer recommendations.Documentation

Maintain detailed records of calibration activities.

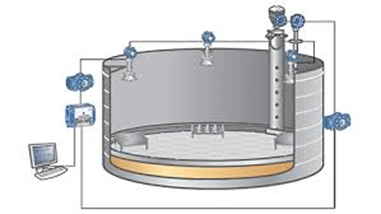

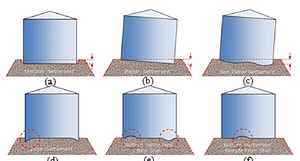

Storage Tanks Inclination

Overview

Monitoring and correcting storage tank inclination is essential in the oil and gas industry to ensure safety and operational efficiency.Importance

Proper inclination prevents structural stress, leakage, and uneven pressure distribution, ensuring safe storage conditions.Causes of Inclination

- Foundation Settlement: Uneven ground support.

- External Factors: Environmental forces like wind or seismic activity.

Monitoring Techniques

- Tilt Sensors: Continuous inclination measurement.

- Periodic Surveys: Manual inspection using leveling tools.

Correction Methods

- Foundation Reinforcement: Stabilizing and leveling the base.

- Tank Adjustment: Re-positioning or realignment of the tank.

Documentation

Maintain records of inclination measurements and corrective actions.

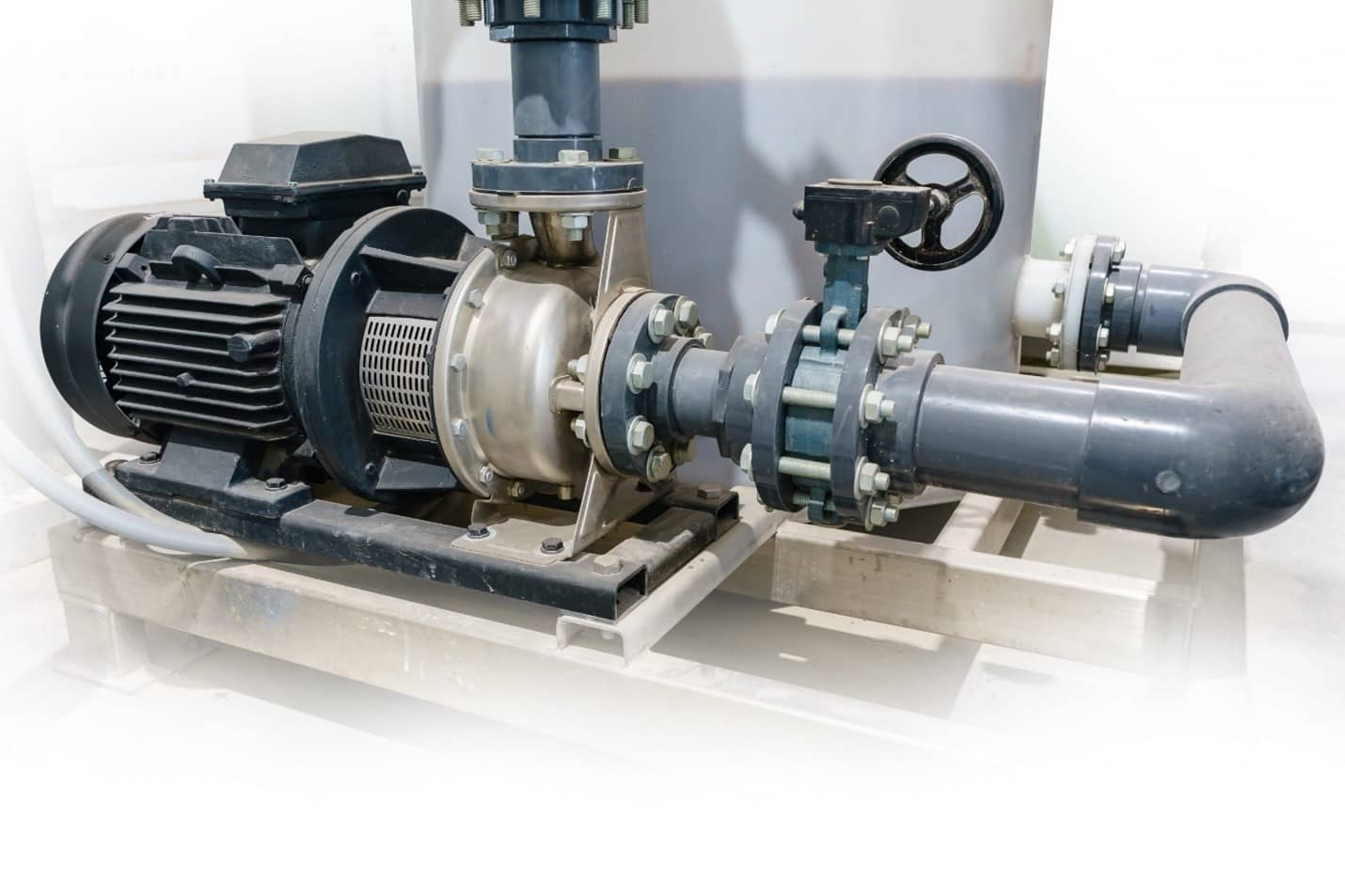

Rotary Equipment

Overview

Rotary equipment refers to machinery that operates with rotational motion, essential for various oil and gas processes.Types

- Pumps: Used for transporting fluids such as crude oil or water.

- Compressors: Increase pressure in gas pipelines.

- Turbines: Convert fluid energy into mechanical energy.

- Fans and Blowers: Circulate air or gas in processes.

Key Functions

- Fluid Handling: Movement of liquids and gases.

- Energy Conversion: Transforming fluid power into mechanical work.

- Process Optimization: Enhancing efficiency and reliability.

Maintenance Considerations

- Vibration Monitoring: To detect potential issues.

- Lubrication Systems: Ensuring smooth operation.

- Regular Inspections: Prevent breakdowns and ensure safety.

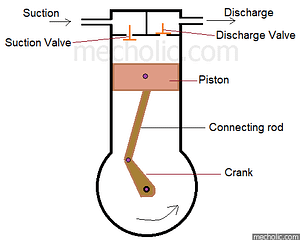

Reciprocating Compressors

Overview

A reciprocating compressor is a mechanical device that uses a piston to compress gas, commonly employed in the oil and gas industry for various applications.

Key Components

- Cylinder: Houses the piston for gas compression.

- Piston: Moves within the cylinder to compress gas.

- Valves: Control the intake and release of gas.

- Crankshaft: Converts rotary motion into reciprocating motion.

Functions

- Gas Compression: Increases pressure in pipelines.

- Storage: Compresses gas for transportation and storage.

- Energy Conversion: Enhances operational efficiency.

Maintenance Considerations

- Vibration Analysis: To monitor performance.

- Lubrication: Ensures smooth operation.

- Valve Inspection: For efficient compression.

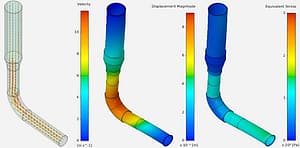

Piping Vibration

Overview

Piping vibration occurs when pipes experience oscillatory motion due to fluid flow, mechanical forces, or environmental factors, affecting the integrity of oil and gas systems.Causes

- Flow-Induced Vibration: Turbulence in the flow of liquids or gases.

- Mechanical Vibrations: Equipment like pumps and compressors causing vibrations.

- External Forces: Environmental or operational factors, such as wind or seismic activity.

Impact

- Fatigue Failure: Prolonged vibration can lead to cracks or ruptures.

- Noise Pollution: Excessive vibration may produce loud noise.

- Operational Inefficiency: Affects system performance.

Mitigation Strategies

- Vibration Monitoring: Installing sensors to detect vibration levels.

- Support Systems: Adding supports or braces to minimize movement.

- Regular Maintenance: Ensuring all components are functioning properly.

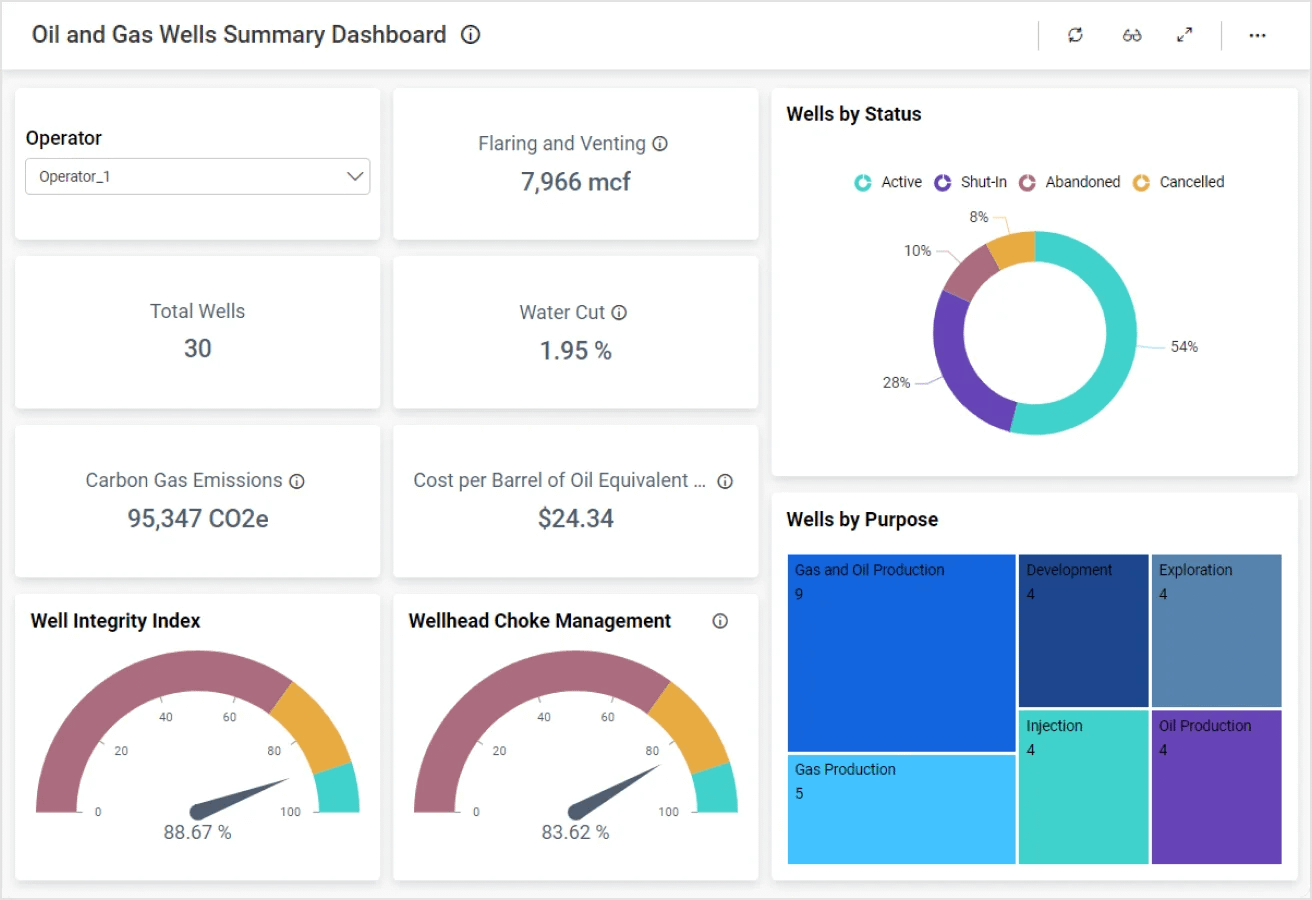

AI Based Condition Monitoring

Overview

AI-based condition monitoring leverages artificial intelligence to assess the health of equipment, predicting failures and optimizing performance in oil and gas operations.Key Components

- Data Sensors: Collect real-time data on equipment performance.

- AI Algorithms: Analyze patterns and detect anomalies.

- Predictive Maintenance: AI predicts potential failures before they occur.

- Remote Monitoring: Allows real-time surveillance from distant locations.

Benefits

- Increased Reliability: Reduces unplanned downtime.

- Cost Savings: Lowers maintenance costs through early detection.

- Improved Safety: Minimizes risks by detecting issues before they become critical.

Applications

- Pump and compressor monitoring

- Pipeline health analysis

- Predictive maintenance for rotary equipment

Health Industry

Audiometric Calibrators

Importance of Calibration

Regular calibration of audiometers is vital in ensuring accurate hearing assessments. It helps maintain the precision of tests, which is crucial for diagnosing and treating hearing impairments.Calibration Process

The process involves adjusting the audiometer's settings to standardized reference levels. This minimizes measurement errors and ensures the accuracy of the data collected during hearing tests.

Standards and Compliance

Proper calibration requires specialized equipment and trained personnel. It is essential to follow industry standards to ensure the reliability of audiometric results.Environmental Monitoring

Weather Monitoring Stations

Overview

A weather monitoring station is a setup used to collect and record meteorological data, essential for tracking environmental conditions and predicting weather patterns.Key Components

- Temperature Sensors: Measure ambient temperature.

- Anemometer: Records wind speed and direction.

- Barometer: Measures atmospheric pressure.

- Rain Gauge: Collects and quantifies rainfall.

- Humidity Sensors: Track moisture levels in the air.

Functions

- Data Collection: Gathers real-time weather data.

- Weather Forecasting: Assists in predicting weather changes.

- Environmental Impact Assessment: Monitors local climatic conditions.

Applications

- Agricultural planning

- Disaster management

- Climate research

- Air quality monitoring

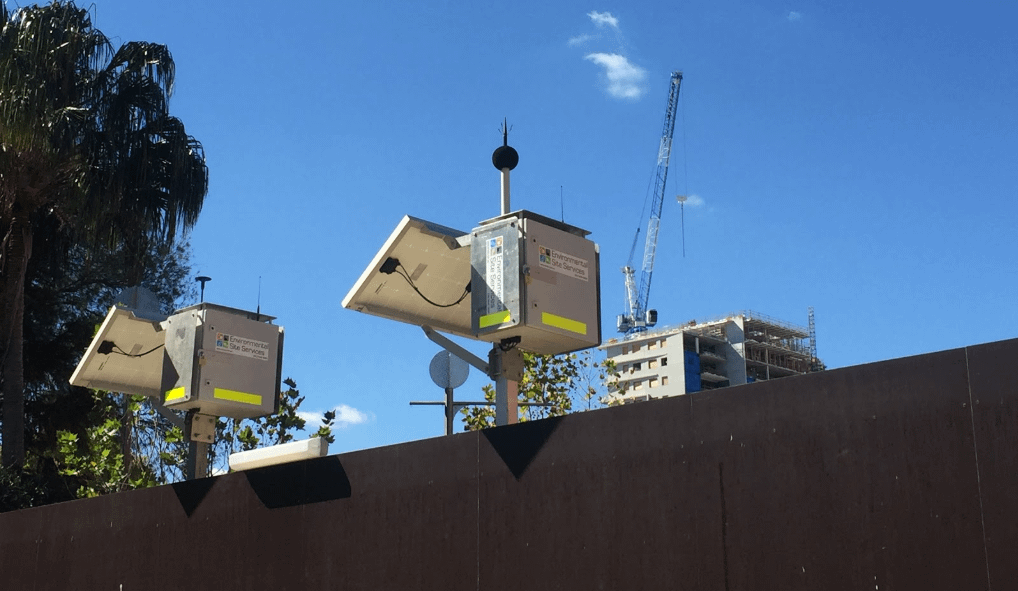

Noise Monitoring

Overview

Noise monitoring involves the measurement and analysis of sound levels in various environments to assess their impact on human health, wildlife, and overall environmental quality.

Key Components

- Sound Level Meters: Devices that measure sound intensity.

- Microphones: Capture noise levels for analysis.

- Data Loggers: Record and store noise data for assessment.

- Software: Analyzes sound patterns and generates reports.

Functions

- Environmental Impact Assessment: Evaluates noise pollution in urban and industrial areas.

- Compliance Monitoring: Ensures adherence to noise regulations.

- Public Health Protection: Identifies harmful noise levels affecting communities.

Applications

- Urban planning

- Industrial site monitoring

- Construction noise control

- Wildlife habitat assessment

Education

Vibration Testing Lab

Calibration Labs

Construction Industry

Strctural Health Monitoring

Ground Vibration

Agriculture

Forest Fire Weather Station

Introduction

A Forest Fire Weather Station is a crucial component in monitoring and preventing forest fires. It gathers real-time meteorological data to assess fire risk.Key Features

- Temperature and Humidity Sensors: Measure ambient temperature and relative humidity.

- Wind Speed and Direction: Provides critical information on wind patterns.

- Rain Gauges: Monitor precipitation levels.

- Solar Radiation Sensors: Assess the potential for dry conditions.

Importance in Agriculture

These stations help protect agricultural land adjacent to forests by providing early warnings and data for effective fire management strategies.

Automatic Agricultural Meteorological station

Introduction

An Automatic Agricultural Meteorological Station is essential for modern farming, providing real-time weather data to optimize agricultural practices.Key Features

- Temperature and Humidity Sensors: Monitor the microclimate conditions affecting crops.

- Rain Gauges: Measure precipitation to inform irrigation needs.

- Soil Moisture Sensors: Track soil moisture levels for effective water management.

- Wind Speed and Direction Sensors: Help in understanding wind patterns that affect spraying and crop health.