Overview

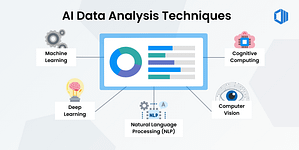

AI-based condition monitoring leverages artificial intelligence to assess the health of equipment, predicting failures and optimizing performance in oil and gas operations.

Key Components

- Data Sensors: Collect real-time data on equipment performance.

- AI Algorithms: Analyze patterns and detect anomalies.

- Predictive Maintenance: AI predicts potential failures before they occur.

- Remote Monitoring: Allows real-time surveillance from distant locations.

Benefits

- Increased Reliability: Reduces unplanned downtime.

- Cost Savings: Lowers maintenance costs through early detection.

- Improved Safety: Minimizes risks by detecting issues before they become critical.

Applications

- Pump and compressor monitoring

- Pipeline health analysis

- Predictive maintenance for rotary equipment