Technologies

You are here:

- Home

- Technologies

- Page 2

Technologies

You are here:

- Home

- Technologies

- Page 2

Test & Measurement Sensor

Vibration Shakers

Torque Transducer

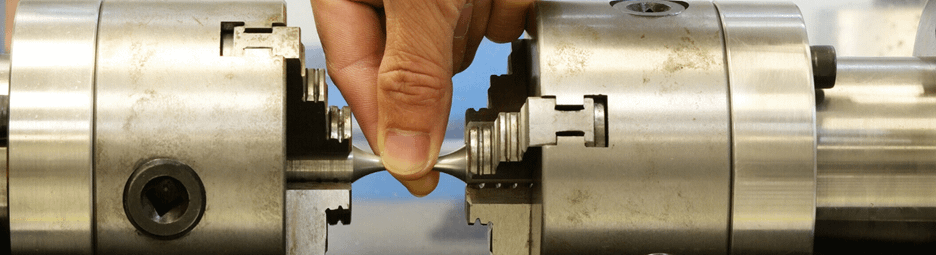

Our torque transducers are advanced instruments engineered to accurately measure and monitor torque in a variety of mechanical systems. They work by converting the rotational force applied to an object into an electrical signal, providing precise and reliable torque data. These transducers are essential for applications such as automotive testing, industrial machinery calibration, and research and development projects. They are designed to deliver high accuracy and stability, even in demanding environments, ensuring optimal performance and safety. With features like wide measurement ranges, high sensitivity, and robust construction, our torque transducers are crucial for optimizing machinery, validating performance, and enhancing operational efficiency across various industries.

Strain Sensor

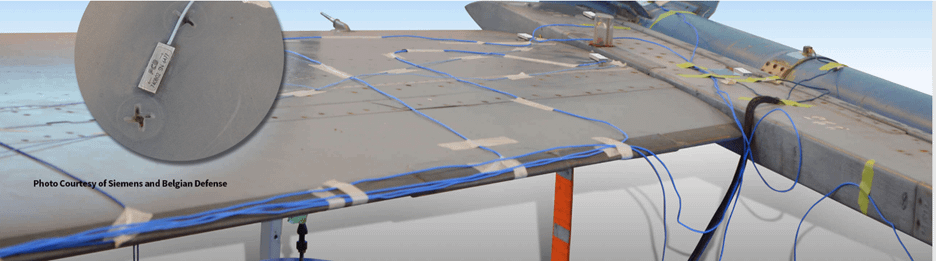

Our strain sensors are precision instruments designed to measure the deformation or strain experienced by materials and structures under various loads. By converting mechanical strain into an electrical signal, these sensors provide accurate and real-time data on stress, tension, and compression. Ideal for applications in structural health monitoring, aerospace, civil engineering, and industrial machinery, our strain sensors help ensure the integrity and safety of critical systems and components. With high sensitivity, durability, and a range of measurement capabilities, our sensors enable detailed analysis and reliable performance monitoring, supporting maintenance strategies and enhancing overall operational efficiency.

Applications

Process monitoring- Control press forces & other processes

- Monitor quality, safety, & reliability

- Composite material testing

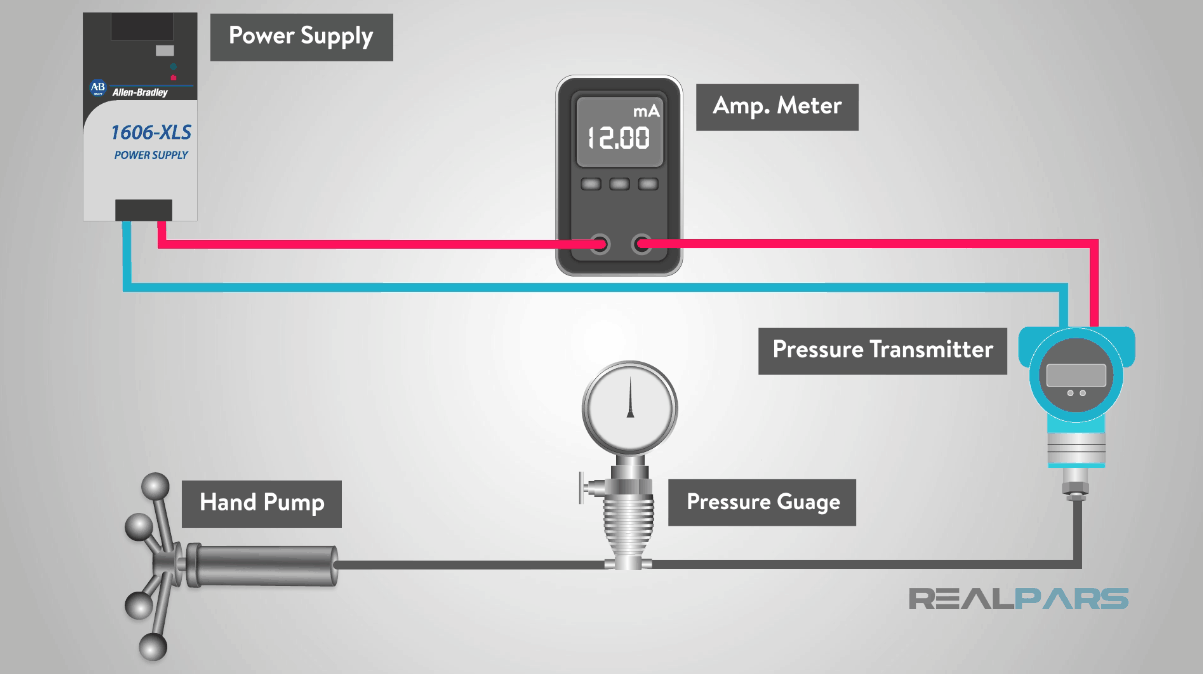

Pressure Sensor

Pressure sensors are devices used to measure the pressure of gases or liquids, converting the pressure into an electrical signal that can be monitored and analyzed. They are widely used across various industries, including manufacturing, automotive, aerospace, and HVAC systems, to ensure safe and efficient operation of equipment and processes. Pressure sensors play a crucial role in applications such as monitoring fluid levels, detecting leaks, regulating system pressures, and ensuring proper functioning of pumps and compressors. By providing real-time data on pressure conditions, these sensors help in maintaining optimal performance, preventing equipment failures, and enhancing overall system reliability. There are various types of pressure sensors, including absolute, gauge, differential, and vacuum sensors, each tailored to specific applications. Their accuracy, reliability, and ability to operate in harsh environments make pressure sensors an essential component in modern automation, control systems, and safety mechanisms.

Impact Hammers

Impact hammers are precision tools designed for accurate impact testing and analysis across various industrial and research applications. These hammers deliver controlled, repeatable impacts to materials and structures, providing critical data on mechanical properties such as hardness, elasticity, and structural integrity. Ideal for material testing, quality control, and equipment calibration, Impact hammers feature robust construction and advanced functionality, ensuring reliable and consistent performance. Their ease of use and durability make them essential for engineers, researchers, and maintenance professionals seeking detailed insights into material behaviour and system performance. Applications:

- Structure Health Testing

- Resonance Determination

- Modal Analysis

Force Sensor

Our force sensors are expertly designed to provide precise measurement of applied forces across a range of applications. These sensors convert mechanical forces, such as tension, compression, and shear, into accurate electrical signals, delivering real-time data essential for various industrial, research, and quality control processes. Engineered for high sensitivity and durability, our force sensors ensure reliable performance even in demanding environments. They are ideal for use in structural testing, automation systems, and product validation, offering critical insights that enhance operational efficiency, safety, and product quality. With robust construction and advanced features, our force sensors are a key component for achieving accurate and consistent force measurement.

Acoustics

Our range of acoustic gadgets is designed to enhance sound quality and manage noise effectively across various environments. From precision audio equipment to advanced noise-cancellation devices, our products cater to both professional and personal needs. We offer high-fidelity microphones, soundproofing solutions, and acoustic treatment tools that improve audio clarity, reduce unwanted noise, and optimize sound performance. Whether you're outfitting a recording studio, upgrading home audio systems, or managing environmental noise, our acoustic gadgets provide innovative solutions to achieve superior sound quality and control. Explore our selection to find the perfect tools for your acoustic needs.

Accelerometers

Our accelerometers are designed to measure acceleration forces with precision, capturing both static forces like gravity and dynamic forces such as vibrations and movements. These devices convert acceleration into electrical signals, providing essential data for a wide range of applications. Ideal for machinery monitoring, automotive systems, consumer electronics, and aerospace engineering, our accelerometers help detect and analyze vibrations, impacts, and motion changes. This information is crucial for maintaining equipment reliability, improving safety, and enhancing performance. Available in various types, including capacitive, piezoelectric, and MEMS (Micro-Electro-Mechanical Systems), our accelerometers are integral to advancing technology and driving efficiency in numerous industries.

Solar & EV Testing Tools

Solar Panel Testing Instruments

Electric Vehicle Safety Testing

Railway Road & Transportation System

Transport Data Logger

Shock Data Logger

Rail & Wheel Profile Measurement Tools

Compact Data Logger

Brake & Switch Crossing Measurement Tools

Online Monitoring System

Structural Health Monitoring

Ground Vibration Monitoring System

Environmental Monitoring System

Noise Monitoring System

Vibration Monitoring System

Noise Dosimeter

Our noise dosimeters are specialized devices designed to measure an individual's exposure to noise over time, ensuring compliance with occupational health and safety standards. Compact and wearable, these dosimeters provide precise, real-time data on noise levels, capturing both continuous and peak sound exposures. They are essential for assessing noise exposure in workplaces, such as manufacturing facilities, construction sites, and other noisy environments, where monitoring and controlling noise levels is crucial for worker safety. Featuring user-friendly interfaces and robust data logging capabilities, our noise dosimeters help in evaluating compliance with regulations, identifying potential hearing risks, and implementing effective noise control measures.

Human Vibration Meter

Our human vibration systems are designed to assess and monitor the impact of vibration exposure on individuals, particularly in occupational settings where vibrations from machinery or equipment are prevalent. These systems measure how vibrations are transmitted to the human body, helping to evaluate potential health risks and ensure compliance with safety standards. Equipped with advanced sensors and data analysis tools, our systems provide accurate insights into vibration levels, duration, and frequency, enabling effective management of vibration-related health risks. By offering detailed assessments, our human vibration systems support the implementation of strategies to protect workers and improve overall workplace safety.

Environmental Noise Monitoring

Portable Sound Level Meter-Based Solutions

Portable sound level meters offer flexibility for temporary assessments in various locations. These devices are ideal for short-term monitoring projects and compliance checks. They provide accurate noise level measurements and are easy to transport, making them suitable for diverse environments.

Permanent Sound Level Meter-Based Solutions

Permanent sound level meters are installed in fixed locations to continuously monitor noise levels. These systems provide long-term data for environmental impact assessments and urban planning. They help identify noise sources, assess impacts on communities, and implement effective noise control measures.

Industrial Sensor

Vibration Switches

Vibration switches are safety devices used to protect rotating and reciprocating machinery by monitoring vibration levels and triggering alarms or shutdowns when vibrations exceed preset thresholds. These switches are crucial for preventing damage caused by excessive vibration, which can result from imbalances, misalignments, bearing failures, or other mechanical issues. By instantly detecting abnormal vibration levels, vibration switches help to avoid catastrophic failures, reduce unplanned downtime, and minimize repair costs. They are widely used in applications such as pumps, compressors, fans, and motors, providing a simple yet effective solution for basic vibration protection. Vibration switches are easy to install and maintain, making them an accessible and cost-effective component of an overall condition monitoring strategy.

Vibration Sensor

Vibration sensors, also known as accelerometers or vibration transducers, are critical components in condition monitoring systems used to detect and analyze vibration levels in machinery. These sensors convert mechanical vibrations into electrical signals that can be measured and analyzed to assess the health of equipment. By monitoring parameters such as amplitude, frequency, and velocity, vibration sensors help identify potential issues like imbalance, misalignment, bearing defects, or gear problems before they lead to significant failures. They are widely used in various industries to monitor equipment such as motors, pumps, turbines, and compressors. Vibration sensors provide valuable data that supports predictive maintenance, helping to reduce downtime, extend machinery lifespan, and improve overall operational efficiency. Their precise measurements and real-time monitoring capabilities make them indispensable tools for maintaining the reliability and safety of rotating equipment.

Pressure Sensor

Pressure sensors are devices used to measure the pressure of gases or liquids, converting the pressure into an electrical signal that can be monitored and analyzed. They are widely used across various industries, including manufacturing, automotive, aerospace, and HVAC systems, to ensure safe and efficient operation of equipment and processes. Pressure sensors play a crucial role in applications such as monitoring fluid levels, detecting leaks, regulating system pressures, and ensuring proper functioning of pumps and compressors. By providing real-time data on pressure conditions, these sensors help in maintaining optimal performance, preventing equipment failures, and enhancing overall system reliability. There are various types of pressure sensors, including absolute, gauge, differential, and vacuum sensors, each tailored to specific applications. Their accuracy, reliability, and ability to operate in harsh environments make pressure sensors an essential component in modern automation, control systems, and safety mechanisms.

Enclosures

Enclosures are protective housings designed to safeguard electronic components, equipment, and machinery from environmental factors such as dust, moisture, chemicals, and physical impacts. They are essential in various industries, including manufacturing, telecommunications, energy, and automation, where sensitive equipment needs protection to ensure reliable operation and longevity. Enclosures are made from materials like metal, plastic, or fiberglass and come in various sizes and designs to accommodate different applications, from small electronic devices to large industrial systems.They not only protect against environmental hazards but also help in organizing components, managing cable systems, and providing security against unauthorized access. By using the right enclosures, companies can enhance the safety, performance, and maintenance of their equipment, ensuring consistent and efficient operations in diverse and challenging environments.

Electronics

We specialize in providing cutting-edge electronic gadgets that enhance everyday life with innovation and convenience. Our extensive range of products includes the latest in smart home devices, wearables, audio equipment, and personal electronics, all designed to keep you connected, entertained, and efficient. We carefully curate our selection to offer only high-quality, reliable gadgets from top brands, ensuring that our customers have access to the best technology on the market. Whether you’re looking to upgrade your home, stay ahead with the latest tech trends, or find the perfect gift, This is is your one-stop shop for all your electronic needs. Experience the future of technology with our exceptional customer service, fast shipping, and a passion for making life easier and more enjoyable through electronics.

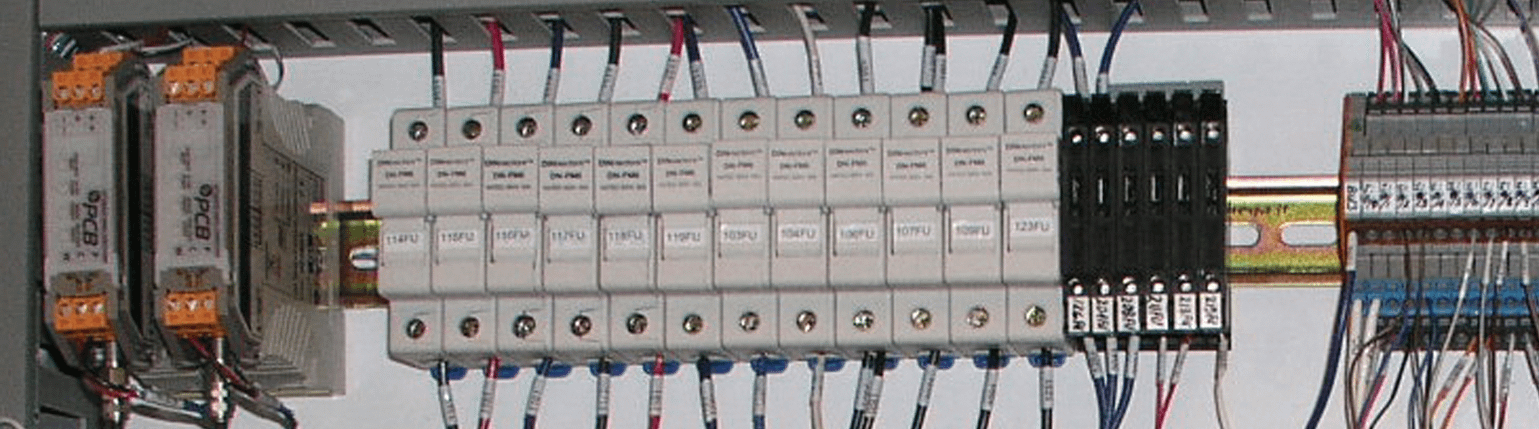

Cables

GTI provide robust cable assemblies designed to endure harsh environments for predictive maintenance, process monitoring, and power generation applications. Selecting the correct cable assembly is crucial for the effective installation and operation of sensors, as cables are often the first point of failure in vibration systems. Our assemblies feature connectors from reliable suppliers and are meticulously engineered to ensure durable cable-to-connector interfaces. Each cable assembly undergoes rigorous testing against extreme conditions, including high temperatures (up to 500 °F / 260 °C), extremely low temperatures (-320 °F / -196 °C), nuclear environments, rugged applications, chemical corrosion, moisture, and dust. GTI offer a comprehensive range of industrial cable assemblies and bulk cable spools, including options with polyurethane and PTFE jackets. Our product lineup includes field-installable 2- and 3-pin MIL connectors, 4-pin bayonet connectors, and 4-pin M12 connectors. We provide two-conductor cables for single-axis accelerometers, as well as three- and four-conductor cables suitable for multi-axis accelerometers, temperature output accelerometers, and 4-20 mA vibration transmitters, ensuring reliable performance across a variety of demanding applications.

Accessories

Adhesive mounting pads, magnets, spot face tools, mounting studs, motor fin mounts, probe tips, and epoxy are essential tools for installing industrial accelerometers. Adhesive pads, made from resilient stainless steel, ensure accurate and repeatable measurements by providing a stable mounting surface, whether tapped for stud-mounted sensors or untapped for magnetic sensors. Magnetic mounts offer convenient temporary installation with high attraction forces, ideal for high-frequency applications and curved surfaces. Spot face tools create smooth surfaces and pilot holes for sensor mounting. Epoxy kits securely bond sensors to machinery, with options for small and large quantities. Data collection extension poles facilitate easy access to measurement points while avoiding heat sources. We also provides compatible cables, connectors, and high-temperature bushings for modern data collectors.

4-20mA Vibration transmitters

Our 4-20mA vibration transmitters are engineered to provide accurate and reliable measurement of vibration levels in industrial settings. These transmitters convert vibration data into a standardized 4-20mA signal, which is widely used for integrating with control systems and monitoring equipment. Ideal for applications such as machinery health monitoring, predictive maintenance, and process control, our vibration transmitters offer real-time data to help detect potential issues early and prevent costly downtime. Designed for durability and performance, they ensure consistent operation in challenging environments, making them a crucial component for effective vibration analysis and maintenance strategies.

Condition Monitoring Tools

Vibration Measurement Tools

US Testing Tools

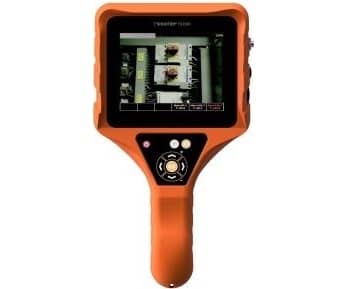

Thermography Monitoring Tools

In the field of condition monitoring, specifically within temperature inspection, thermal imaging cameras are often seen as the go-to solution for detecting temperature defects. However, it's not always as straightforward as it seems. With our new product, we've discovered an alternative method to detect and highlight temperature issues more effectively. While infrared cameras and contactless temperature measurement tools are widely used in preventive maintenance, we've noticed that many technicians, even with years of experience, struggle with thermal analysis. Our approach prioritizes the technician's workflow, focusing on providing user-friendly, efficient tools that simplify their tasks and enhance job satisfaction.

Shaft Alignment Tools

Shaft alignment tools are critical in ensuring the precise alignment of rotating machinery components such as shafts, which is essential for optimal performance and longevity. These tools help detect and correct alignment issues, minimizing vibration, reducing wear and tear, and preventing premature failures. Advanced shaft alignment tools, such as laser alignment systems, provide highly accurate measurements, making the alignment process quicker and more efficient compared to traditional methods. Proper alignment reduces energy consumption, lowers maintenance costs, and enhances the overall reliability of equipment. In environments where reducing downtime and maximizing asset performance are priorities, shaft alignment tools are indispensable for maintaining smooth and efficient operations.

Motor Testing Tools

Leak Testing Tool

Our advanced Ultrasonic Leak Detector is meticulously engineered to deliver precise and reliable leak detection for a wide range of products. Featuring an intuitive control interface and sophisticated software, our system ensures accurate leak identification and consistent, repeatable results. The detector's versatile testing capabilities accommodate various products, from small electronic devices to large mechanical assemblies, adapting seamlessly to different test requirements. Equipped with state-of-the-art ultrasonic sensors and robust construction, our Ultrasonic Leak Detector provides highly accurate and dependable outcomes, ensuring products can withstand real-world conditions without leakage.

Equipment Balancing Tools

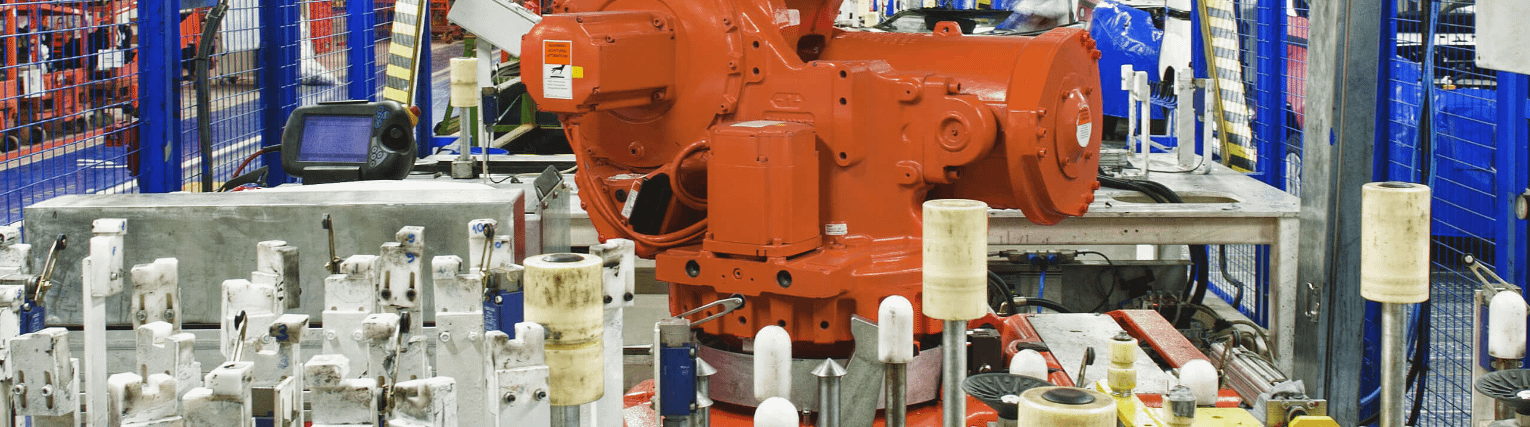

Our advanced Equipment Balancing Tool is meticulously engineered to deliver precise and reliable balancing for a wide range of machinery and components. Featuring an intuitive control interface and sophisticated software, our system ensures accurate balance correction and consistent, repeatable results. The tool's versatile capabilities accommodate various equipment, from small rotating components to large industrial machines, adapting seamlessly to different balancing requirements. Our Equipment Balancing Tool provides highly accurate and dependable outcomes, ensuring machinery operates smoothly and efficiently. Customizable test parameters allow for tailored balancing procedures, speed settings, and correction methods to meet specific needs while adhering to industry standards. Safety is paramount, and our system incorporates multiple safety features to protect both the operator and the equipment, ensuring compliance with international safety standards. Ideal for industries such as automotive, aerospace, manufacturing, and power generation, our Equipment Balancing Tool helps enhance machinery reliability, ensure compliance with regulatory standards, and reduce the risk of equipment failure due to imbalance, ultimately saving costs and improving operational efficiency. Contact us today to discover how our Equipment Balancing Tool can elevate your maintenance and quality assurance processes.

Calibration System & Shakers

Vibration Test Chamber

Our advanced Vibration Test Chamber is meticulously engineered to deliver precise and reliable vibration testing for a wide range of products. Featuring an intuitive control interface and sophisticated software, our system ensures accurate vibration simulations and consistent, repeatable results. The chamber's versatile testing capabilities accommodate various products, from small electronic devices to large mechanical assemblies, adapting seamlessly to different test requirements. Equipped with state-of-the-art sensors and robust construction, our Vibration Test Chamber provides highly accurate and dependable outcomes, ensuring products can endure real- world vibrations and stresses. Customizable test parameters allow for tailored vibration frequencies, amplitudes, and durations to meet specific needs while adhering to industry standards. Safety is paramount, and our system incorporates multiple safety features to protect both the operator and the equipment, ensuring compliance with international safety standards. Ideal for industries such as automotive, aerospace, electronics, and manufacturing, our Vibration Test Chamber helps enhance product reliability, ensure compliance with regulatory standards, and reduce the risk of product failure due to vibrational stresses, ultimately saving costs and improving customer satisfaction. Contact us today to discover how our Vibration Test Chamber can elevate your product development and quality assurance processes.

Shock Test Systems

Our state-of-the-art Shock Test System is engineered to deliver precise and reliable shock testing for a wide range of products. This advanced system features an intuitive control interface and sophisticated software, ensuring precise shock pulse generation and repeatability. Its versatile testing capabilities accommodate various products, from small electronics to large mechanical components, adapting seamlessly to different test requirements. With cutting-edge sensors and robust construction, our Shock Test System provides highly accurate and reliable results, ensuring products can withstand real-world conditions. Customizable test parameters allow for tailored shock pulses, durations, and amplitudes to meet specific needs while adhering to industry standards. Safety is paramount, and our system includes multiple safety features to protect both the operator and the equipment, ensuring compliance with international safety standards. Ideal for industries such as automotive, aerospace, electronics, and packaging, our Shock Test System helps enhance product reliability, ensure compliance with standards, and reduce the risk of product failure, ultimately saving costs and improving customer satisfaction. Contact us today to discover how our Shock Test System can elevate your product development and quality assurance processes.

Pressure Sensor Calibration System

The Modal Shop offers specialized calibration systems for dynamic pressure sensors, which are typically calibrated by modifying the amplitude of the input signal. Our solutions cater to a broad spectrum of pressure measurement applications, including atmospheric blast experiments, gas turbine exhaust fluctuations, internal combustion engine measurements, ammunition brass calibrations, and hydraulic or fuel line measurements. Leveraging the expertise and metrology heritage of PCB Piezotronics, our systems have been rigorously tested and validated through tens of thousands of factory calibrations. Our cutting-edge digital hardware and software platform ensures precise and reliable calibration, meeting the exacting demands of industrial and research applications.

| Range psi (MPa) | Uncertainty | |

| Low Pressure | 150 (1.0) | ±1.5 % |

| Medium Pressure | 1 000 (6.9) | ±1.5 % |

| High Pressure | 15 000 (103.4) | ±4.1 % |

| Ultra-High Pressure | 80 000 (550) | ±2.0 % |

| Shock Tube | 1 000 (6.9) | - |

Mid-Level Dynamic Pressure Sensor Calibration

Our system provides low-pressure transient inputs to the sensor under test, in accordance with ANSI B88.1 standards. It offers a pressure range of 5 to 150 psi, or 1 MPa, allowing for precise calibration of sensors.

Mid-Level Dynamic Pressure Sensor Calibration

Our system provides low-pressure transient inputs to the sensor under test, in accordance with ANSI B88.1 standards. It offers a pressure range of 5 to 150 psi, or 1 MPa, allowing for precise calibration of sensors.

High Level Dynamic Pressure Sensor Calibration

Our high-level dynamic pressure sensor calibration system provides accurate calibration using impulse input, with a wide pressure range of 100 to 15,000 psi (103.4 MPa) for high-pressure sensor testing.

High Level Dynamic Pressure Sensor Calibration

Our high-level dynamic pressure sensor calibration system provides accurate calibration using impulse input, with a wide pressure range of 100 to 15,000 psi (103.4 MPa) for high-pressure sensor testing.

Ultra-High Level Dynamic Pressure Sensor Calibration

Our ultra-high level dynamic pressure sensor calibration systems offer extreme pressure calibration up to 80,000 psi (550 MPa) for specialized applications like ammunition brass and oil testing.

Ultra-High Level Dynamic Pressure Sensor Calibration

Our ultra-high level dynamic pressure sensor calibration systems offer extreme pressure calibration up to 80,000 psi (550 MPa) for specialized applications like ammunition brass and oil testing.

High Frequency Instrumented Shock Tube

Our High Frequency Instrumented Shock Tube (K9901C) is a unique system that tests pressure sensors by generating shock waves through diaphragm rupture. The system measures incident and reflected pressures, delay time, and ambient conditions, with pressure levels reaching up to 1,000 psi (6.9 MPa).

High Frequency Instrumented Shock Tube

Our High Frequency Instrumented Shock Tube (K9901C) is a unique system that tests pressure sensors by generating shock waves through diaphragm rupture. The system measures incident and reflected pressures, delay time, and ambient conditions, with pressure levels reaching up to 1,000 psi (6.9 MPa).

Portable Vibration Shaker and Calibrator

Take your vibration calibration and troubleshooting to new heights with Portable Vibration Calibrators from The Modal Shop! These advanced devices feature a built-in sensitivity display, enabling instant detection of sensor drift and ensuring accurate vibration alarm operation. With the ability to calibrate various sensor types and store calibration reports, these calibrators make it easy to impress auditors and risk engineers. They offer versatility, calibrating ICP, voltage, charge mode, modulated current, and piezoresistive sensors in any vibration scale, and have built-in memory storing pre-loaded stepped sine calibration routines with pass/fail notification. Designed for durability, they boast a rugged design and long battery life, and ensure accuracy. Upgrade your vibration calibration and troubleshooting with these powerful, portable devices!

Portable Vibration Calibrator with Sensitivity Display

Bring precision to the plant floor with portable vibration sensor calibration and validation. Cover a wide frequency range of 5 Hz to 10 kHz for accurate equipment performance. Streamline processes with efficient on-site calibration and validation.

Modal Testing and Vibration Testing Shaker

Microphone Calibration System

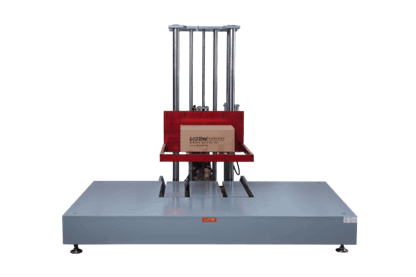

Drop Test Systems

Our cutting-edge Drop Test System is designed to provide precise and dependable drop testing for a diverse array of products. This advanced system features an intuitive control interface and sophisticated software, ensuring accurate drop simulations and consistent results. Its versatile testing capabilities accommodate various items, from delicate electronics to robust mechanical components, seamlessly adapting to different test requirements. Equipped with state-of-the-art sensors and sturdy construction, our Drop Test System delivers highly accurate and reliable outcomes, ensuring products can withstand real-world handling and impacts. Customizable test parameters allow for tailored drop heights, orientations, and impact surfaces to meet specific needs while adhering to industry standards. Safety is a top priority, and our system incorporates multiple safety features to protect both the operator and the equipment, ensuring compliance with international safety standards. Ideal for industries such as consumer electronics, packaging, automotive, and aerospace, our Drop Test System helps enhance product durability, ensure compliance with regulatory standards, and reduce the risk of product damage during transit, ultimately saving costs and improving customer satisfaction. Contact us today to learn how our Drop Test System can enhance your product development and quality assurance processes.